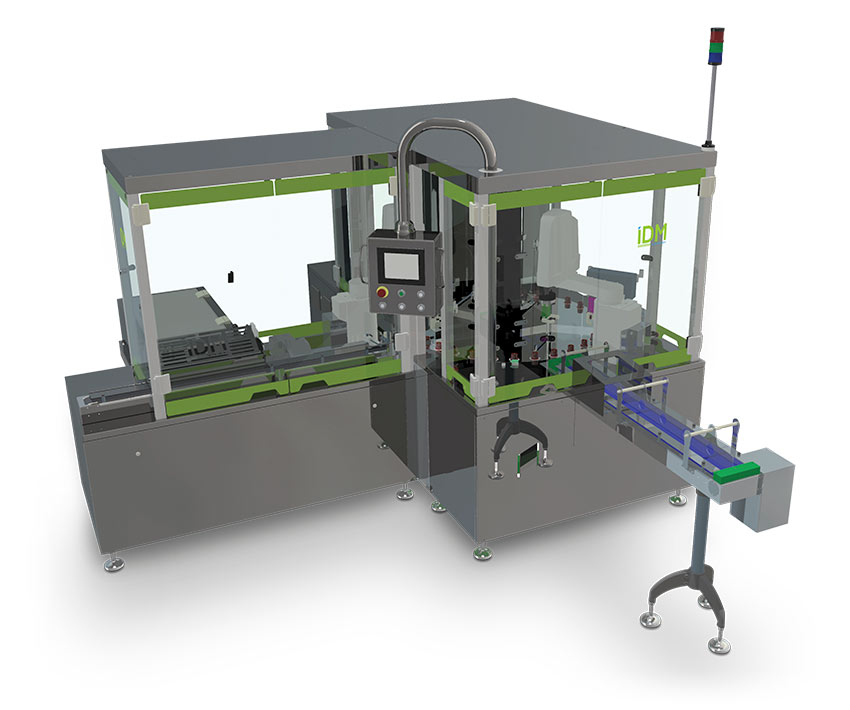

All-In-one e-MF-302 Pure

Automatic technological solution intended for filling bottles made of different materials. Machinery designed to fill and close bottles of heterogeneous shapes, characterized by versatility of use, both in the decorative field and for the treatment of body and hair. Solution characterized by a 30-position rotary table with a 20 mm thick anticorodal disc covered with polished 304 BA stainless steel sheet, with removable and interchangeable bushing supports at format change. The solution can be customized by adding production modules and the required level of automation. Full-electric version. Being completely electric, the e-MF302 has been enriched with a series of pluses: it is more performing; more environmentally friendly, allowing great energy savings; extremely silent, thus ensuring great working comfort.

All-In-one e-MF-302 Pure

Technical data

Machine dimensions

6250 x 3910 mm, h 2000 mm

Productivity

Up to 3600 pcs/h

Supported formats

Min diameter: 10 mm

Max diameter: 45 mm

Min length: 40 mm

Min length: 110 mm

PERFORMANCE

- Productivity: up to 60ppm

- Speed and precision of setting when changing format

- Accuracy and certainty in movements through the use of controlled axes

- Easy cleaning thanks to the use of mirror-polished stainless steel and glass guards

- Easy replacement of the dosing head which does not require the use of tools

+ GREEN

- Respect for the product and the environment following the non-use of compressed air

+ SAVING

- Lower usage costs

- Lower direct maintenance costs

- Absence of purchase and maintenance costs for air compressors and related systems

+ SILENCE & WELNESS

- Reduced acoustic impact

- Ergonomic workstation