SPS: the trade fair for the smart industry

SPS Parma is the trade show that is dedicated to innovations belonging to the smart industry. Finally, after a forced two-year stop due to the pandemic, SPS is back with its 10th edition.

The fair will be held in Parma from May 24 to 26, allowing free admission to all industry professionals from 9:30 am to 6 pm.

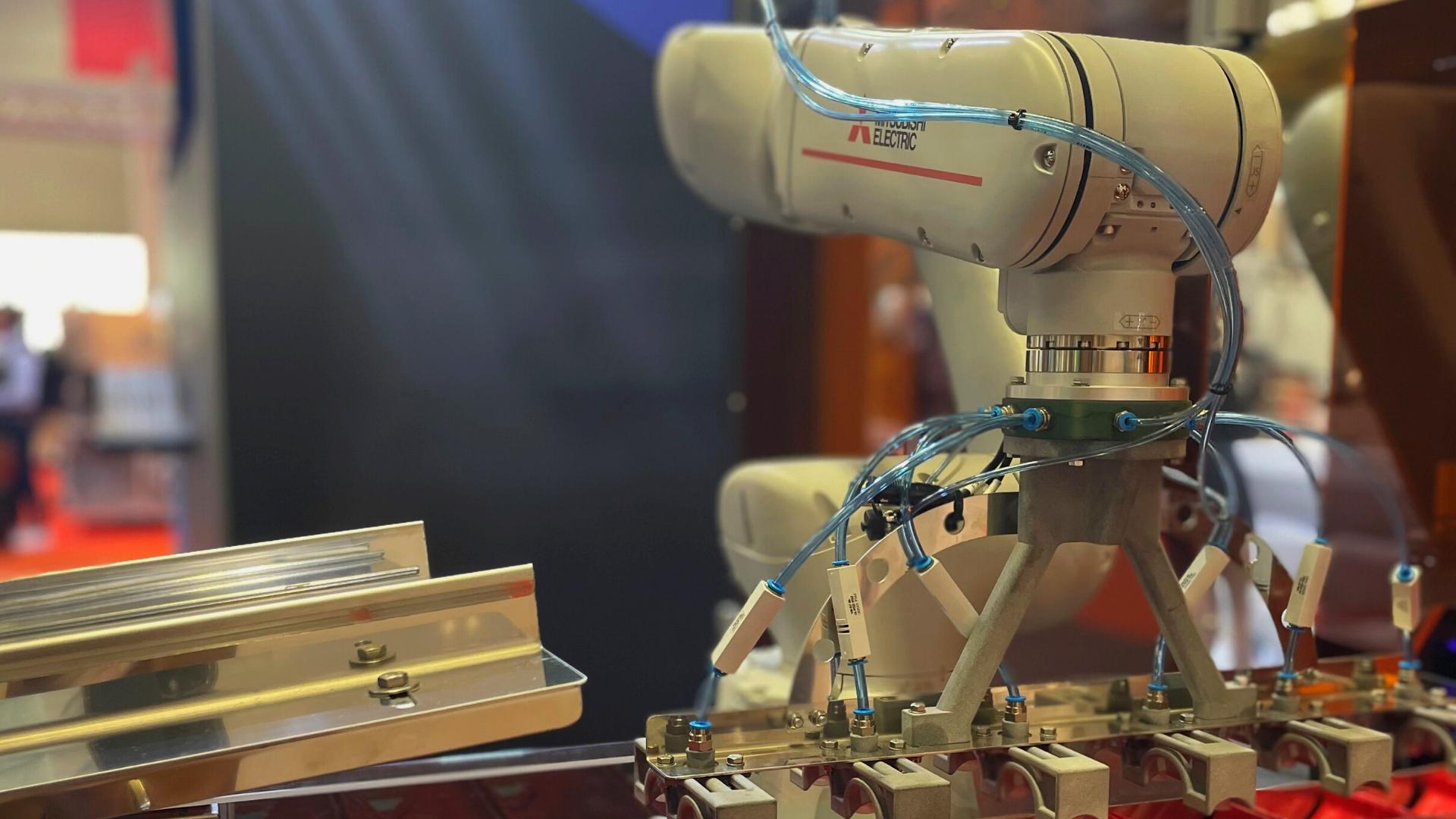

We at IDM Automation could not miss participating together with Mitsubishi Electric at Hall. 6 booth g20-e20 contributing with our latest highly appreciated “concept innovations,” as we like to call them.

An opportunity for industry professionals

SPS Italia offers countless opportunities for networking, educational meetings, workshops and conferences. All useful tools to broaden one’s network of knowledge and discover new trends in the rising industry.

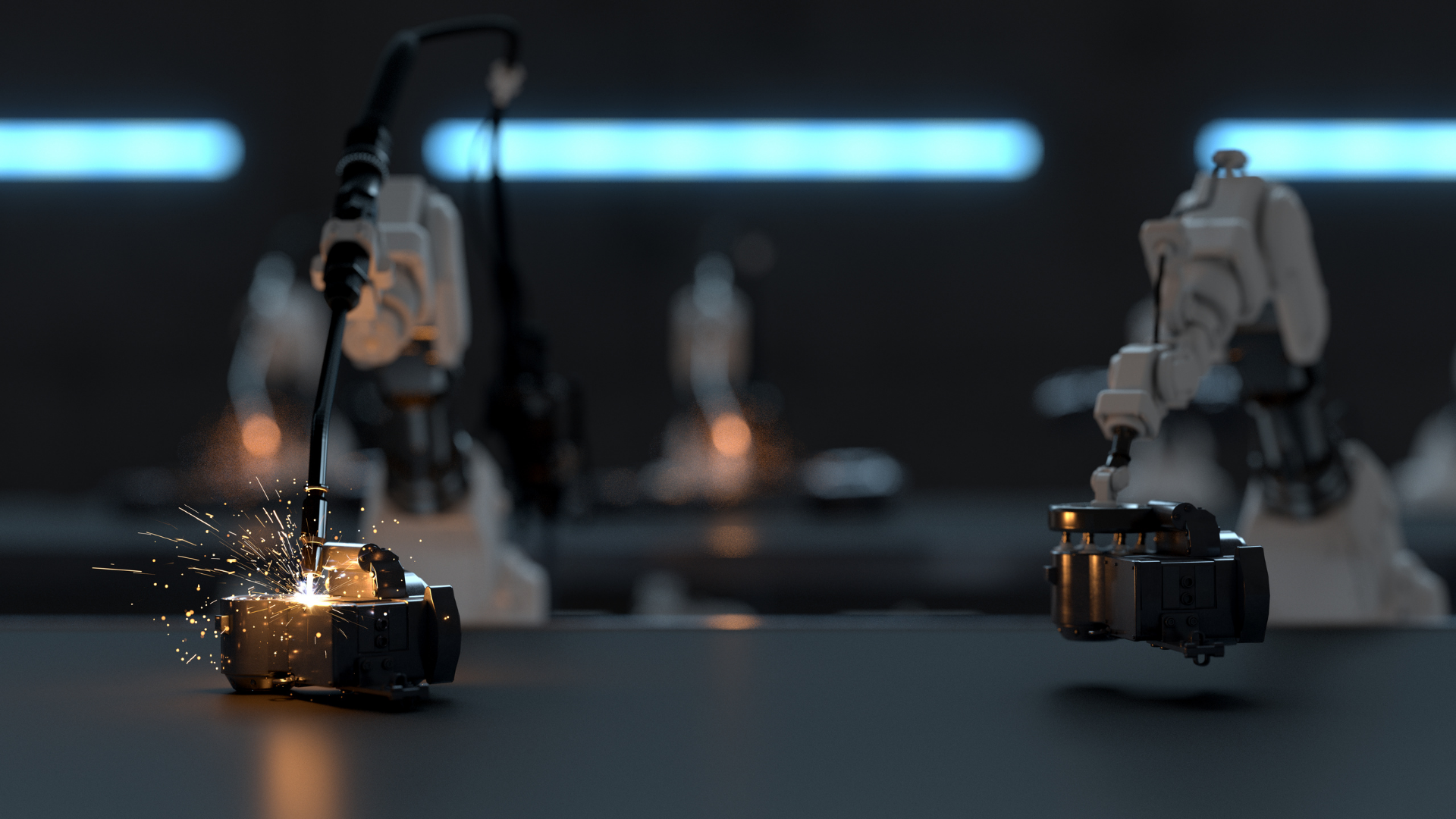

The SPS Parma exhibition space is organized into six pavilions, three of which are dedicated to District 4.0, which in turn consists of four areas: robotics and mechatronics, advanced automation, additive manufacturing and digital & software. In these areas, it will be possible to preview the operation of latest-generation automated machines and see hands-on demonstrations of machine operation.

The focus of this edition

The focus of this 10th edition is first and foremost on sustainability, an issue that now cuts across all sectors.

Indeed, more and more innovations in the field of smart industry are being made with sustainability of processes and materials used in mind and prioritized.

In addition, this year’s edition of the SPS fair is focused heavily on automation and precision machinery for small packaging.

Visit us

For this reason, the IDM Automation team could not resist participating and contributing. We will be attending the fair in partnership with Mitsubishi Electric to present the new Printing & Filling line, PF-220, inaugurated a few weeks ago at Cosmoprof.

This is an innovative concept that, thanks in part to the partnership with Quantix Digital, makes it possible to print directly on round packaging made of plastic, aluminum and other materials, without printing plates and, above all, without the need for labeling.

The novelty of this Printing & Filling plant lies, moreover, in the possibility of not being constrained by product quantities, since with this line it is possible to print neutral containers and then customize them only when needed.

This is an extremely precise industrial process, capable of printing 85 pieces per minute and filling 60 pieces per minute, with sensors regulating activity, with a filling capacity of up to 250 ml.

Our digital printing and filling equipment simplifies, speeds up processes and ensures that they are carried out with the utmost precision.

If you would like to learn more or see the functioning of the PF-220 – Printing & Filling – line, come visit us at the SPS Italia exhibition from May 24 to 26 at the Mitsubishi Electric booth in Hall. 6 booth g20-e20, we look forward to seeing you there.

Stay updated

Subscribe to our free newsletter.

- 21 June 2022

Automated technologies have enormous potential. Some worry about over-reliance on automation and the possibility of having negative effects on the […]

- 7 June 2022

Why it is important to take care of food packaging Food packaging is very useful in telling and conveying the […]

- 31 May 2022

The tenth edition of SPS Italia After two years of inactivity due to the pandemic, the tenth edition of SPS […]