SPS: the fair for intelligent industry

SPS Parma is the fair par excellence dedicated to innovations belonging to theintelligent industry. Finally, after a forced two-year stop due to the pandemic, SPS returns with the tenth edition.

The fair will be held in Parma from 24 to 26 May, allowing free entry to all operators in the sector from 9.30am to 6.00pm.

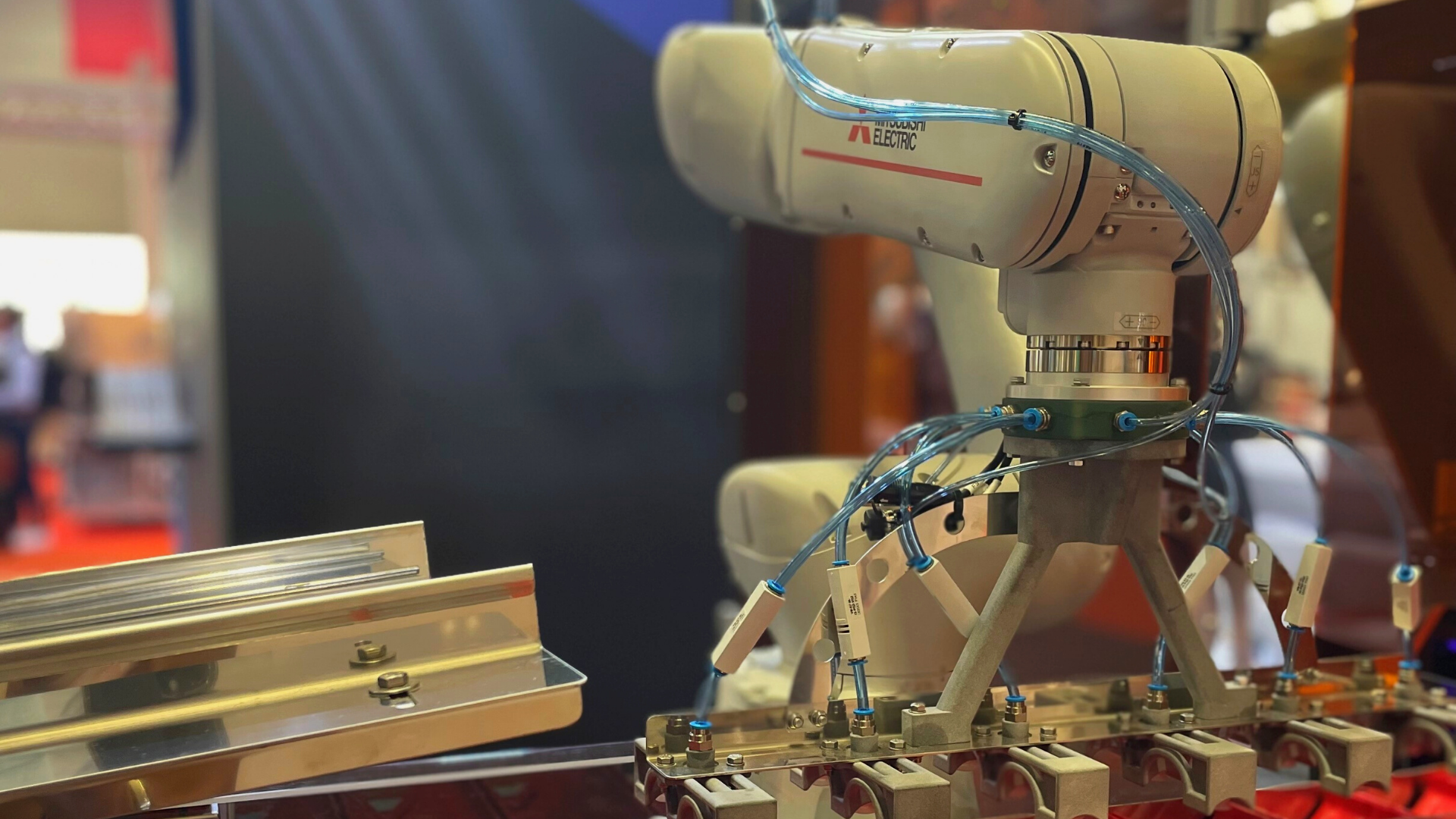

We at IDM Automation couldn't help but participate as a guest of Mitsubishi Electric at pad. 6 stands g20-e20 to contribute our latest highly regarded “concept innovations”, as we like to call them.

An opportunity for operators in the sector

SPS Italia offers countless opportunities for networking, training meetings, workshops and conferences. All useful tools for expanding your network of knowledge and discovering new trends in the growing sector.

The SPS Parma exhibition space is structured on six pavilions, of which three are dedicated to District 4.0, which in turn is made up of four areas: robotics and mechatronics, advanced automation, additive manufacturing And digital & software. In these areas it will be possible to preview the operation of the latest generation automatic machines and attend practical demonstrations of the operation of the machines.

The central point of this edition

The focus of this tenth edition is first and foremost the sustainability, topic now transversal to all sectorthe.

Increasingly innovations in the field of intelligent industryin fact, they are made keeping in mind and giving priority to the sustainability of the processes and materials used.

This year's edition of the SPS fair is also particularly focused on automation machinery and precision for small packaging.

Come and visit us

For this reason the IDM Automation team could not fail to participate and make its contribution. We will be present at the fair in partnership with Mitsubishi Electric to present the new line Printing & Filling, PF-220, inaugurated a few weeks ago at Cosmoprof.

This is an innovative concept which, thanks also to the partnership with Quantix Digital, allows you to print directly on round packaging made of plastic, aluminum and other materials, without printing clichés and, above all, without the need for labelling.

The novelty of this Printing & Filling system also lies in the possibility of do not be limited by product quantities, since with this line it is possible to print neutral containers and then customize them only when needed.

It is an extremely precise industrial process, capable of print 85 pieces per minute and fill 60 pieces per minute, with sensors that regulate activity, with a filling capacity of up to 250 ml.

THE Our digital printing and filling systems simplify and speed up processes and ensure that these are carried out with the maximum precision.

If you want to know more or see how the PF-220 line works – Printing & Filling – come and visit us at the SPS Italia fair from 24 to 26 May at the Mitsubishi Electric stand in pav. 6 stands g20-e20, we look forward to seeing many of you.