Interview with Ivan Riboni, CEO

2022 is the year of news for IDM Automation, news that we want to share at Cosmoprof 2022: from April 28th to May 1st come and visit us at our stand, we will show you our new image and our innovative industrial solutions for filling and printing bottles for nail polish, mascara, gloss, creams, and foundation.

Although there are companies that produce digital printing machines, not all of them are able to manage automated digital printing and filling lines. This is an advantage because it helps the management of small production batches without the use of plastic labels, and it saves time, or logistical or warehouse problems.

Ivan Riboni, CEO of IDM Automation, announced in an interview the innovations planned for 2022.

Clearly, the first one concerns the rebranding: a new logo with new colors and a new design, the creation of a new website and, above all, the desire to put the word “Automation” at the same level as “IDM”, to confirm and emphasize the strategic importance of this direction, already undertaken for some time in automation.

The choice of change stems from the desire to breathe some fresh air, thanks to new colors and changes regarding the company image, as well as in the design and core production. After having introduced the new machine for the production of make-up pencils to the market, which we will talk about later, we have other important news in store for Cosmoprof Bologna.

An absolute new entry for Cosmoprof

For more than 50 years, Cosmoprof has been the most important event in the cosmetics industry, where innovation and excellent products meet. IDM Automation will not miss the post-pandemic edition and will be present at Hall 19 Stand C16PK, ready to show you important news.

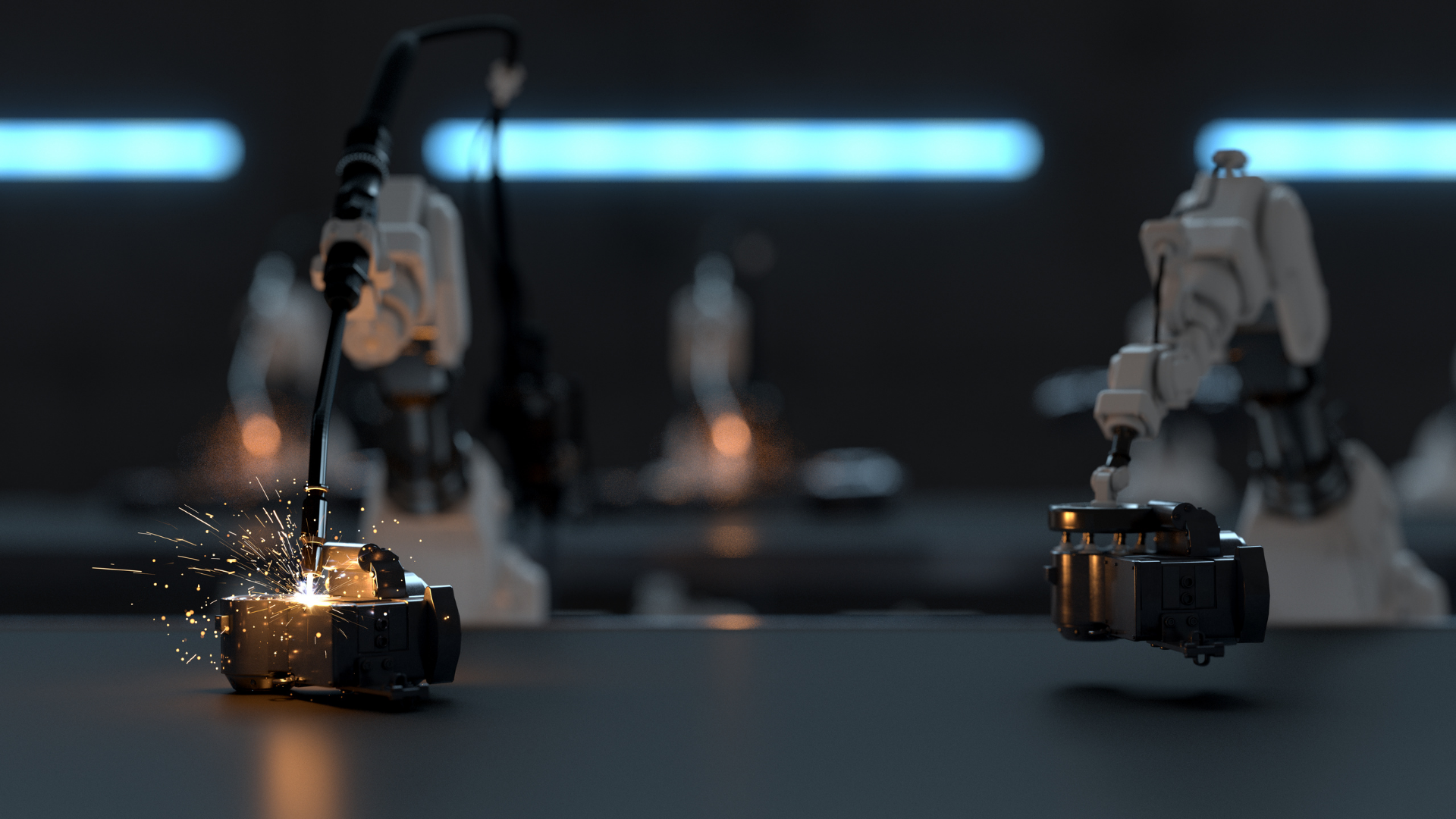

IDM Automation has created a new machine with the collaboration of Quantix Digital, a company that operates in the field of digital printing on round bars. This collaboration has led to the creation of a revolutionary range of products made up of a digital printing machine with an attached tube-filling machine.

The innovation we are pleased to announce consists of processing an aluminum tube without too many assembly lines, including printing and filling. More specifically, it consists of two machines: one that takes care of the digital printing of the tubes and the second of the filling and closing of the tube itself.

The use of an anthropomorphic robot, which allows the transfer of the printed tubes to the loading unit of the tube-filling machines, is the physical demonstration of the company’s new guidelines, confirmed by the CEO: “flexibility, ease of format change thanks to the use of collaborative robots, all of which, of course, Industry 4.0 compliant“.

The real innovation lies in the advantages

The advantage of the new PF-220 line is the combination of printing and filling, which eliminates the several assembly lines that hinder fast production. The possibility of printing directly on the packaging makes it possible to create small production batches or even limited batches for promotional campaigns, which are frequent in the cosmetics sector, while the combination with the tube-filling machines makes it possible to keep blank containers in stock, printing them quickly without quantity constraints.

In this way it is possible to produce the tubes on the spot and, if necessary, fill them, having a product ready for delivery and free from intermediate logistic steps that would slow down the go-to-market.

We look forward to seeing you at Cosmoprof Bologna. Contact us for more information about the latest products.

Stay updated

Subscribe to our free newsletter.

- 21 June 2022

Automated technologies have enormous potential. Some worry about over-reliance on automation and the possibility of having negative effects on the […]

- 7 June 2022

Why it is important to take care of food packaging Food packaging is very useful in telling and conveying the […]

- 31 May 2022

The tenth edition of SPS Italia After two years of inactivity due to the pandemic, the tenth edition of SPS […]